Rings are used for energy storage, similar to springs. Often these, especially the external type of ring, provide shoulders to locate or retain parts on shafts or in cylinders. Internal rings are meant to exert pressure outward and are installed into grooves in housings or bores. Rings have many advantages, in that they’re simple to manufacture, easy to assemble, and offer accurate positioning compared to threaded fasteners.

After coiling, material thickness near the inner surface of the ring is greater than the original material, which must be considered when selecting wire and groove size, and if necessary this can be reduced with secondary operations.

Ring Materials

A ring’s material should be selected based on the environment the part will be used in, however load capacity must be taken into consideration to ensure failure will not occur.

As with all Spiros’ parts, we will custom manufacture any shaped ring to fit your specific needs. Offering competitive pricing, state-of-the-art equipment, and customer satisfaction for over two decades, we’re ready to be part of your team.

To learn more about our products contact us today or request a quote now with our simple contact form.

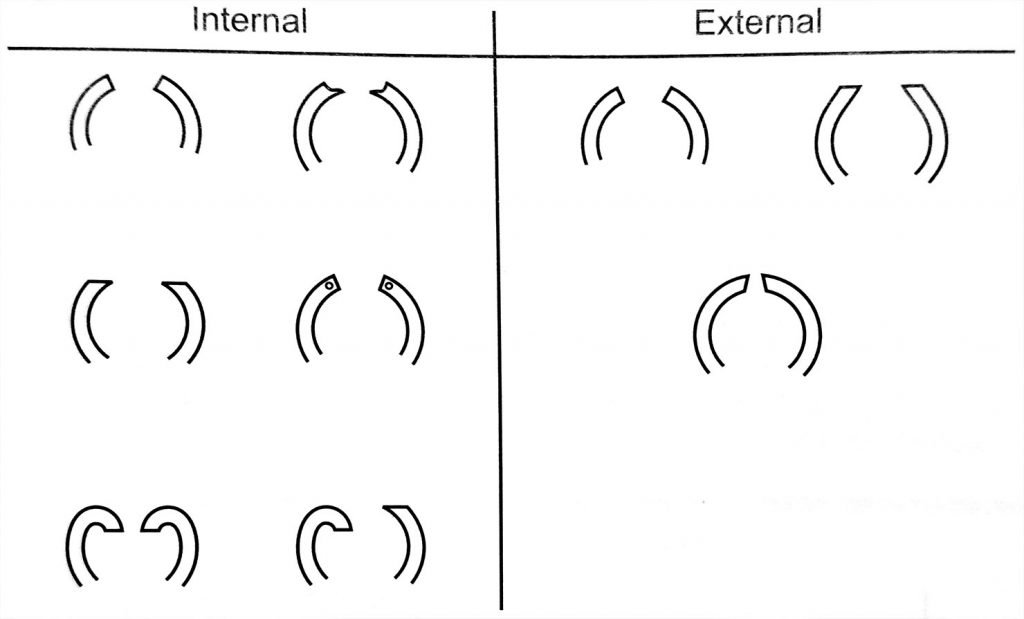

No matter how strict the tolerance of your design may be, we will be able to produce a high-quality product that you can rely on. Rings are often categorized into “internal” and “external”. Below is an expanded list of ring types that we’ve produced:

- Internal Ring

- External Ring

- Expander Ring

- Retaining Ring

- Internal Retaining Ring

- External Retaining Ring

- Snap Ring / Metal Snap Ring

- Custom Snap Rings

- Internal Snap Ring

- External Snap Ring

- Rectangle Wire Snap Ring

- Connecting Ring

- Hose Clamp Ring

- Hydraulic Lock Ring

- Locating Ring

- Locking Ring

- Lock Release Ring

- Piston Ring

- Specialty Rings

- Spiral Ring

Some common end configurations made from rectangular wire are shown below. Ends for round wire rings is limited to inside and outside bends.