Your Partner for Quality Components

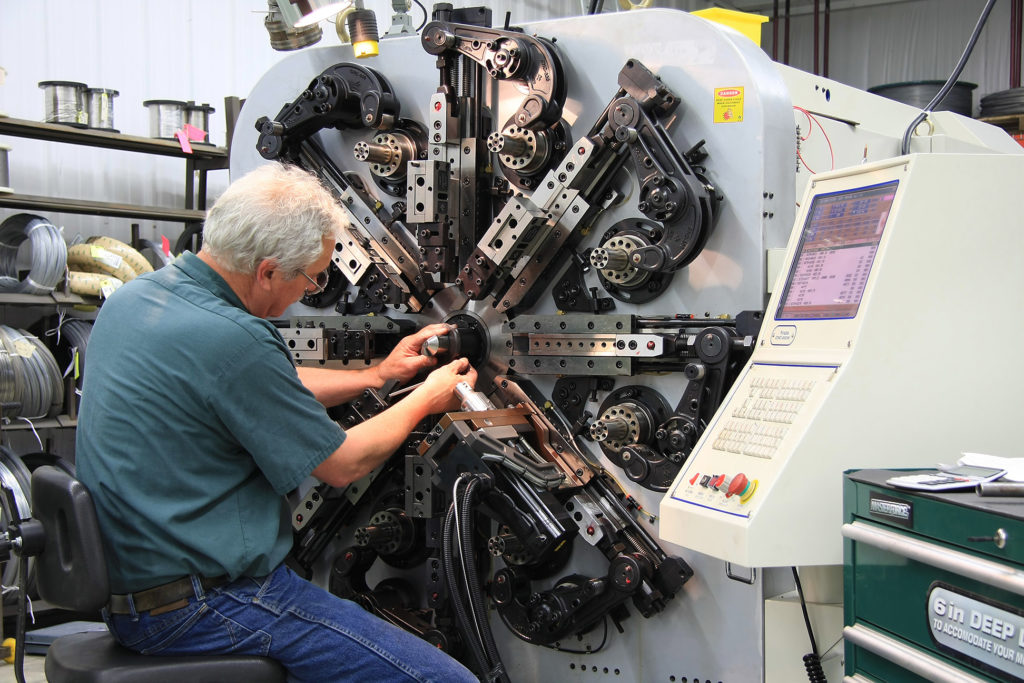

Spiros supports the firearms industry through continued investments in employee training, the latest machinery, materials supply chain and our lean manufacturing processes. As a valued supplier, we extend our capacity to deliver precision and quality with every order.

Spiros manufactures firearms springs for a variety of applications and mission critical functions. We produce our parts on high-speed equipment using the latest quality control technologies. Our state-of-the-art operations allow us to rapidly produce custom magazine springs with strict compliance to your specifications.

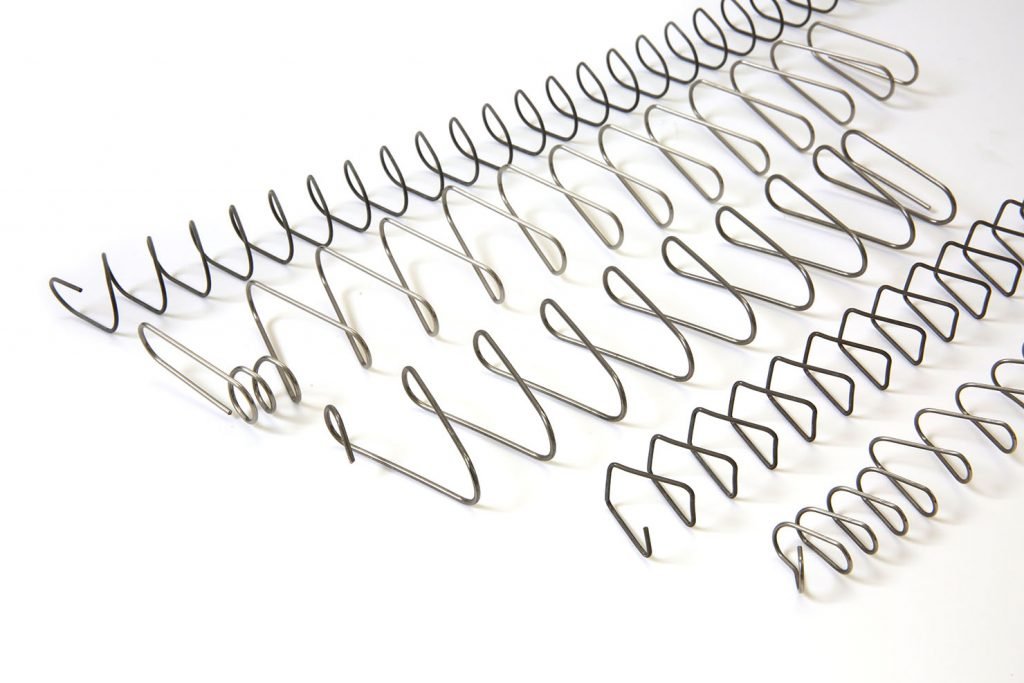

Magazine Springs

Magazine springs are a type of compression spring, with oval or rectangular shaped coils, made for use within firearm magazines to push bullets or rounds into the chamber. These springs must be made with precision and our advanced quality control.

With the various types of firearms comes a variety of spring design possibilities, ranging in length, number of coils, and force needed. Most magazine springs function near their solid height, so rate becomes a very important design factor.

To calculate Rate – the change in load per unit deflection – for a compression spring:

This is only valid when the pitch angle is less than 15° or deflection per turn is less than D/4. For larger deflections per turn, a deflection correction should be used.

Capabilities and Materials

Listed below are some common parts that we manufacture on a regular basis.

- Magazine Springs

- Catch Springs

- Trigger Springs

- Buffer Springs

- Recoil Springs

- Hammer Springs

- Firing Pin Springs

- Striker Springs

Magazine Spring Advanced Materials

Spiros utilizes a wide range of materials in its magazine springs. Although 17-7 is a commonly used stainless steel wire for magazine springs, Spiros is also able to produce parts in a wide variety of standard and specialty materials.

- Stainless Alloys

- Spring Steel

- High Carbon Steel

- Low Carbon Steel

- Nickel Plated Steel

- Hastelloy©

- Elgiloy©

- Iconel©

- Chrome Vanadium

- Chrome Silicon

Custom Applications & Prototypes

As a custom spring manufacturer, Spiros has the engineering expertise and flexibility to work with your original plans or help design a part based on the specific demands of its function. Review and analysis of drawings, prototyping and thorough testing of each custom spring assures its successful application.

As with all Spiros’ parts, we will custom manufacture any magazine or firearm spring to fit your specific needs. Offering competitive pricing, state-of-the-art equipment, and customer satisfaction for over two decades, we’re ready to be part of your team.

To learn more about our products contact us today or request a quote now with our simple contact form.

Secondary Processes

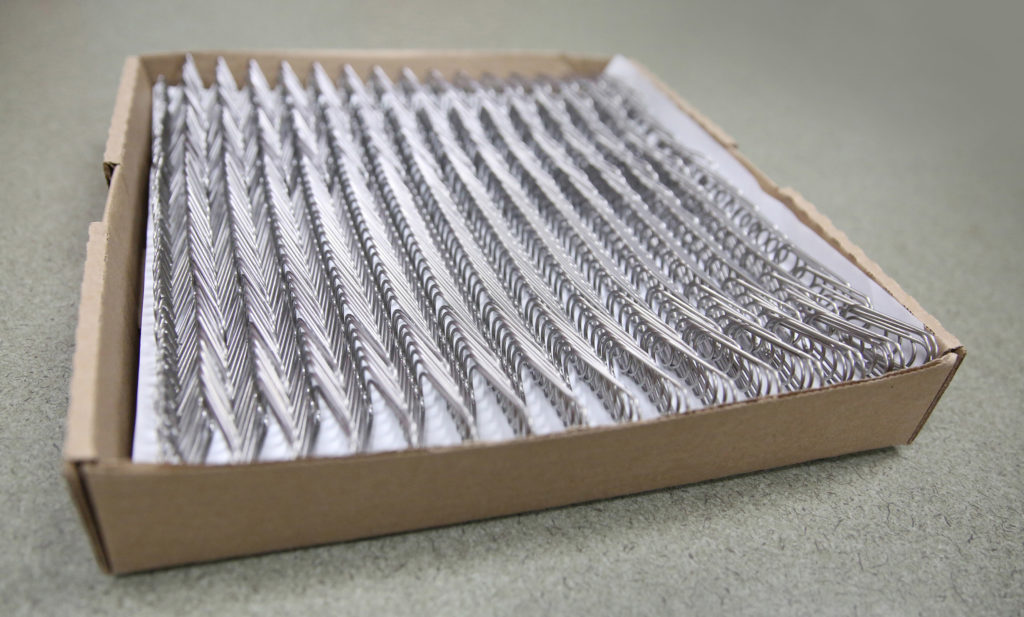

Magazine springs are often used in unique and specialized applications, and it is extremely important that your parts arrive ready for installation in your products. Our secondary processes include passivation, stress-relieving and color coding to improve part performance. Spiros also offers an extensive variety of specialty packaging options to best fit your production environment and workflow requirements. Learn more about our quality control here.

ISO Certifications

Our commitment to world-class quality ensures that our products and services meet or exceed the highest standards set by all U.S. and internationally recognized agencies. Spiros is established as an industry-wide, award-winning supplier with high-quality standards through certifications and continued enforcement of inspection requirements. Learn more about our certifications here.

Experiencing Packaging Challenges?

Challenge accepted. We’ve encountered many unique packaging dilemmas throughout the years, and are confident we can resolve any packaging crisis, for springs and wire forms. Here is an expanded list of some of our packaging capabilities.

As with all Spiros’ parts, we will custom manufacture any magazine or firearm spring to fit your specific needs. Offering competitive pricing, state-of-the-art equipment, and customer satisfaction for over two decades, we’re ready to be part of your team.

To learn more about our products contact us today or request a quote now with our simple contact form.