Compression, or helical compression springs are used to resist applied compression forces or to store energy in the push mode. These are very common and are found in the automotive, aerospace, and consumer industries. This type of spring can take many forms – conical, barrel, hourglass, or cylindrical – but the most common is straight cylindrical. Energy storage capacity is greater for the round wire springs than rectangular, but these other shapes have advantages like reduced solid height, buckling, and surging, or to produce nonlinear load-deflection characteristics.

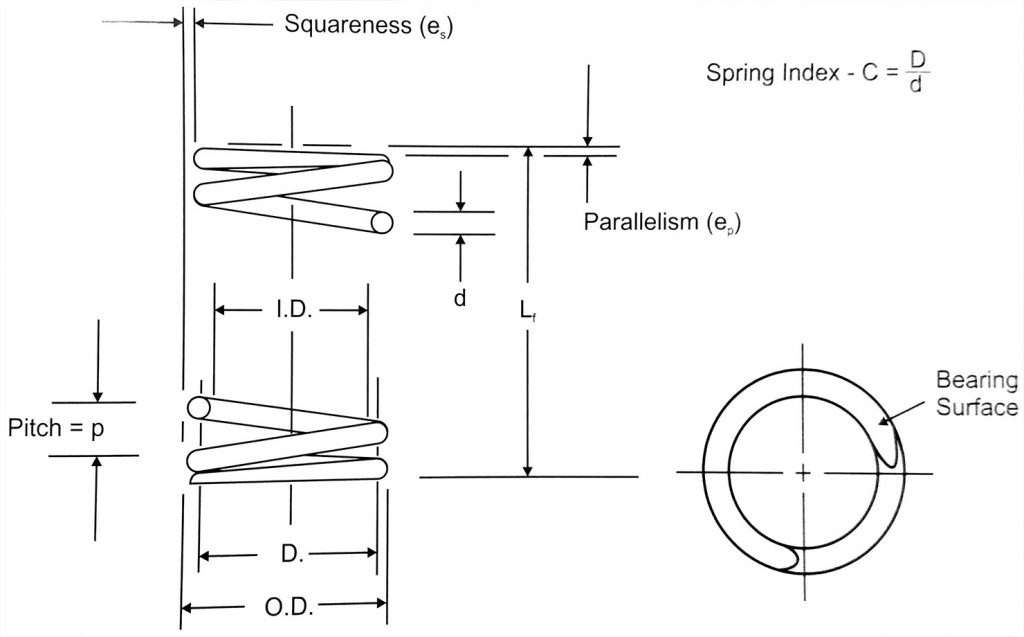

Types of Ends

Compression springs will have a longer life and will sit more squarely when the ends are ground, and as a modern spring manufacturer, our facilities have state-of-the-art equipment which allows this to be done in the most precise way possible. Possible compression spring ends include:

- Plain Ends

- Plain ends ground

- Squared ends – cost less to manufacture than squared ends ground

- Squared ends ground

A bearing surface of at least 270° is required to improve squareness and reduce buckling during operation.

Number of Coils

For springs with squared ends, the number of active coils is the total number of coils minus two. The table below includes guidelines for estimating the number of active coils.

Dimensional Characteristics of Compression Springs

| Open Not Ground | Open and Ground | Closed Only | Closed and Ground |

|---|---|---|---|

|  |  | |

|  |  | |

| Solid Height ( Total Coils ( | |||

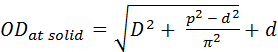

Spring Diameter

OD – outside diameter – specified for springs operating in a cavity

ID – inside diameter – specified for springs operating over a rod, seat, or shaft

D – mean diameter

A minimal diametral clearance between the spring and cavity or rod is:

- 0.05D when DC is greater than 13 mm (0.512”)

- 0.10D when DC is less than 13 mm (0.512”)

Diameter increases slightly when a spring is compressed, so to establish an accurate minimum clearance, where p = pitch:

If the spring ends are allowed to unwind, OD at solid may be greater than this calculation. Long springs buckle and might require lateral support and larger diametral clearances.

Solid Height

The length of a spring with the coils closed. Only if critical, this height should be specified as a maximum dimension and this can be measured by applying a force equal to 110% – 150% of the calculated load at solid. Make allowances for plating or other coatings.[/vc_column_text][vc_column_text]

Spring Rate

This is only valid when the pitch angle is less than 15° or deflection per turn is less than D/4. For larger deflections per turn, a deflection correction should be used.

Spring Index

The ratio of mean diameter to wire diameter or radial dimension of the cross-section. Preferred index range is 4 to 12.

- High index springs tangle easily and may need individual packaging especially if the ends are not squared.

- Springs with an index of less than 4 are difficult to form.

Free Length

The overall spring length in the free or unloaded position. If loads are not critical, the free length can be specified.

P (pitch) is the distance between centers of adjacent coils and is related to free length and number of coils.

The most prevalent form of a compression spring is a straight cylindrical spring. However, other forms such as conical, barrel, hourglass or cylindrical forms are available with custom spacing between coils.

Main Applications

The main application capability for compression springs is to store energy in the push mode or to resist applied compression forces. Compression springs are used in a variety of industries but are most commonly found in automotive, aerospace and consumer goods.

Testimonial

One of the things that I enjoy most about working with Spiros is that, no matter what the situation, I know that I’ll always get what I need.”

Design Considerations

Have You Considered These Factors?

- Diameter increases when a spring is compressed. Was this considered when establishing your minimum clearance?

- Long Compression Springs have a tendency to buckle – especially when their lengths are greater than 4 times their spring diameter. Corrections may require larger diametral clearances and lateral support.

- Preferred Spring Indexes range from 4 to 12. Springs with higher indexes may tangle and often require individual packaging. Springs with lower indexes are typically more difficult to form.

- Different stress conditions (such as elastic condition, direct shear load and static loading at elevated temperatures) require different stress correction factors.

- Under Static Conditions ― To increase the load-carrying ability of springs, increase the length of the spring’s required free length and compress the spring to solid.

- Stress Relaxation can be affected by material, spring processing variable, time, temperature and stress.

- In Cyclic Applications, the velocity of end coils is lower than normal. To set the optimum stress level, you need to balance spring cost versus reliability. The basis of your decision will require complete details concerning the spring application’s operating environment, expected life, stress range, the speed of operation, permissible levels of stress relaxation and the frequency of operation.

- Barrel and Hourglass Springs are calculated as two separate conical springs in a series.

- When a Variable Diameter Spring is designed so that adjacent coils rub against one another during deflection, its resistance to resonance phenomena will increase, but it may also decrease the spring’s longevity.

Helical Compression Springs

Found in many applications, helical compression springs have the most common spring configuration, which consists of round wire coiled into a straight cylindrical spring.Wire Selection

- ROUND WIRE: Has the greater capacity to store energy. Can further increase energy storage by nesting.

- SQUARE WIRE: Reduce solid height Increase design’s space efficiency

Spring Shapes

Helical compression springs are also available in shapes that offer reductions in solid height, buckling and surging or that produce non-linear load-deflection characteristics. Optional Configurations- Conical

- Barrel

- Hourglass

- Cylindrical