Winding and Length

While some torsion springs are open-wound, most are close-wound. When a spring is deflected in the direction that will reduce the coil diameter, body length increases. For applications that require minimum hysteresis, springs should be designed with space between adjacent coils to reduce frictional losses.

Load

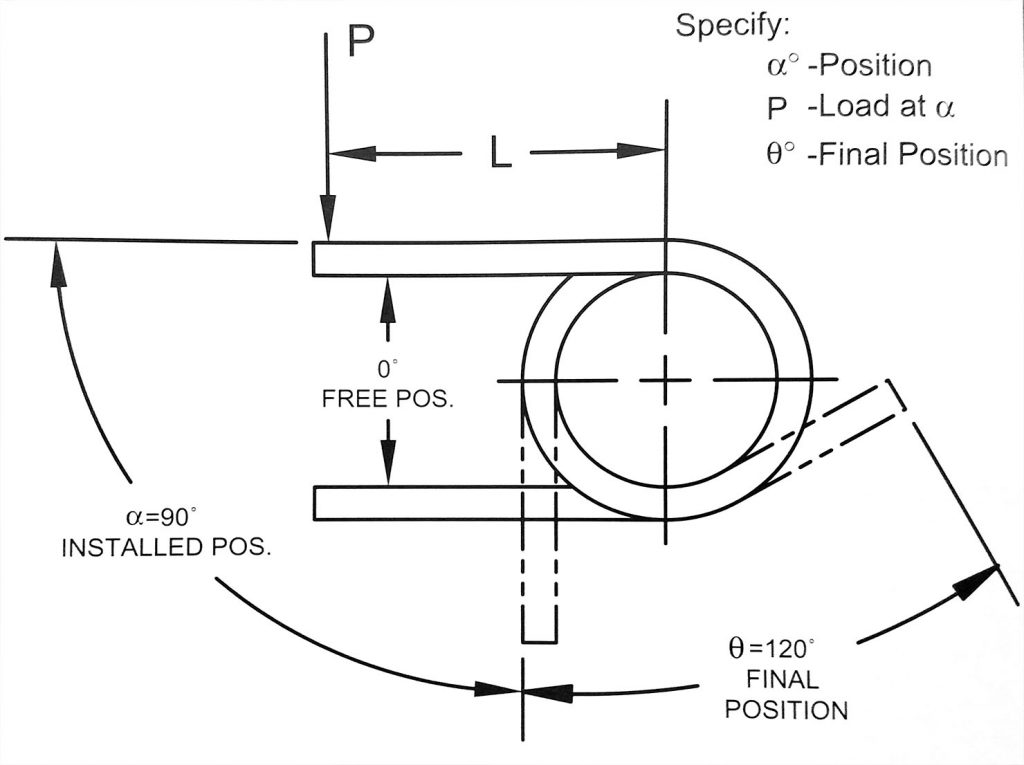

Torsion springs must be supported at three or more points and they should always be loaded in a direction that causes its body diameter to decrease – stresses are favorable in this direction. If however, the direction of loading tends to increase body diameter, the springs must be stress-relieved in production.

Design of Torsion Springs and End Configurations

It’s important to remember that springs loaded to decrease their radius of curvature can operate at higher applied stress levels than bends that increase the radius by loading. Often spring performance is limited due to the sharply bent ends having greater stress than the body. Also be aware that torsion springs are subject to surging and resonance phenomena.

As with all Spiros’ parts, we will custom manufacture any torsion spring to fit your specific needs. Offering competitive pricing, state-of-the-art equipment, and customer satisfaction for over two decades, we’re ready to be part of your team.

To learn more about our products contact us today or request a quote now with our simple contact form.

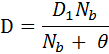

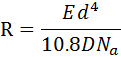

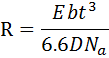

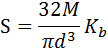

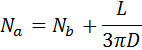

| Equations for All Wire Types | Round Wire | Rectangular Wire On Edge or On Flat |

|---|---|---|

|  |  |

|  | |

| ||

| Initial Mean Diameter ( Wire Diameter ( Stress Correction Factor ( | ||

Diameter

The ideal shaft size is equal to or slightly less than 90% of the inner diameter when the spring is fully deflected (minimum diameter). Shafts significantly smaller than this should be avoided to prevent buckling during large deflections.

Design

For an optimal spring, design it so the applied force is in the direction of the wind to avoid harsh bending stresses.

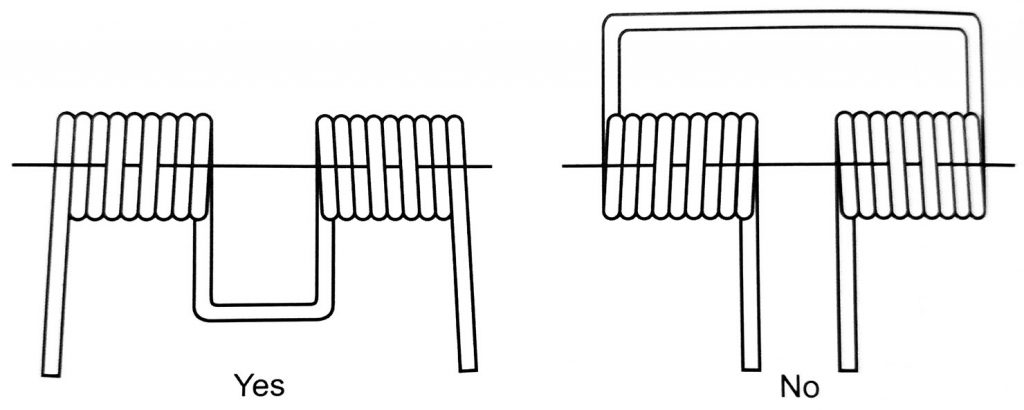

Double Torsion Springs

These are designed using the same methods as for a single-bodied spring. For the same wire diameter, coil diameter, and wire length, these have rated four times those of single-bodied types. These should be designed so they are coiled out from the center, not in from the ends.

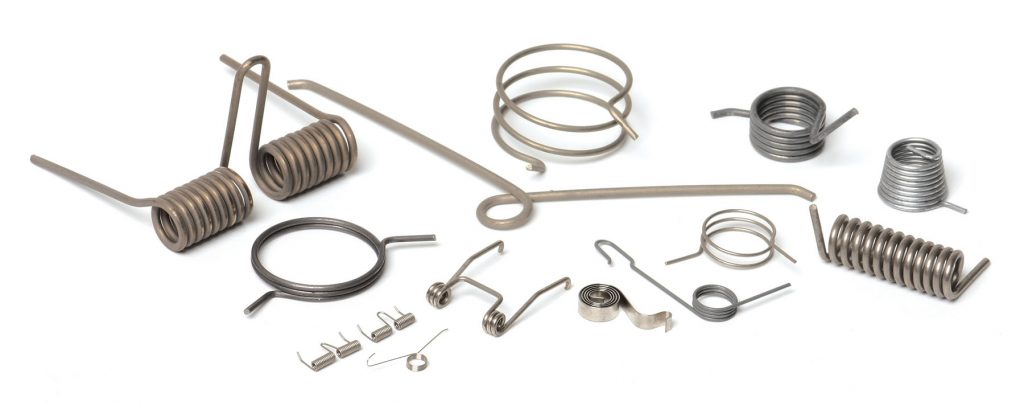

Custom Torsion Springs are produced from rectangular or round wire. It is more typical for a manufacturer to use round wire because of the premium cost of rectangular wire. Additionally, torsion springs are normally heat-treated at a low temperature to stabilize the end positions. These types of springs are used to apply a torque or store rotational energy and can also be referred to as helical springs.

Main Applications

Torsion springs can be found in many day-to-day applications, such as clothespins, ratchets, window shades and other types of machine components.

Design Considerations

Have You Considered These Factors?

- Torsion Spring Shaft — Shafts that are much smaller than 90% should be avoided – otherwise buckling may occur during large deflections.

- Minimum Hysteresis — Torsion spring applications that require minimum hysteresis, reduce their frictional loss by adding space between adjacent coils.

- Torsion springs are capable of surging or resonance phenomena.

- Load and Deflection Requirements — Specify torsion spring loads at a Fixed Angular Position instead of fixed deflection from the free position.

- Torsion Spring Stress — Bending is the main cause of stress in Torsion Springs and may require a stress correction factor configured during design.

- When designing ends with sharp bends, the wire may be stretched or marked and may cause stress concentrations leading to a reduction in design stress levels that may fall below-recommended levels. (NOTE: Friction occurs at the point of contact between the torsion end and the arbor, which induces a higher stressed area.)

- Double Torsion Springs and single torsion springs are designed with the same methods. (NOTE: Design double torsion springs so they coil out from the center instead of coiling in from the ends.)

Testimonial